Lithium Complex Grease

Product Details:

- Operating Temperature -20C to +180C (peak up to +200C)

- Chemical Composition Lithium Complex Thickener, Mineral Base Oil, Additives

- Application Automotive, Industrial, Bearings, Chassis, Wheel Bearings

- Packaging Type Standard Export Packaging

- Weight Customized

- Use Lubrication under high temperature and heavy load

- Oil Type Mineral Oil

300 INR/Carton

X

Lithium Complex Grease Price And Quantity

- 300 INR/Carton

- 10 Carton

Lithium Complex Grease Product Specifications

- Automotive, Industrial, Bearings, Chassis, Wheel Bearings

- Lithium Complex Thickener, Mineral Base Oil, Additives

- -20C to +180C (peak up to +200C)

- Max 0.6%

- Smooth and tacky consistency

- Lubrication under high temperature and heavy load

- Lithium Complex Grease

- Mineral Oil

- Standard Export Packaging

- Customized

- Red/Blue/Green (varies by grade)

- Drum, Bucket, Cartridge, Tin

- 500 g, 1 kg, 5 kg, 15 kg, 180 kg

- Mild

- Max 0.1%

- 135 cSt at 40C

- 0.90 Gram per cubic centimeter(g/cm3)

Lithium Complex Grease Trade Information

- 10 Carton Per Day

- 1 Days

Product Description

When choosing bike engine oil its important to consider your bike type engine size and riding conditions Heres a quick guide to help

Types of Bike Engine Oil

1 Mineral Oil

Made from refined crude oil

Best for small older or lowperformance bikes

Needs more frequent changes

2 SemiSynthetic Oil

Blend of mineral and synthetic oils

Good balance of performance and cost

Suitable for midrange bikes and daily commuters

3 Fully Synthetic Oil

Engineered for high performance

Best for sports bikes highrevving engines or long rides

Longer oil life and better protection

Common Viscosity Grades as per SAE

10W30 For smaller engines or colder climates

10W40 20W50 Most common for motorcycles in a range of temperatures

Check your owners manual for the exact recommendation

When to Change the Oil

Mineral oil Every 20003000 km

Semisynthetic Every 40006000 km

Fully synthetic Every 600010000 km

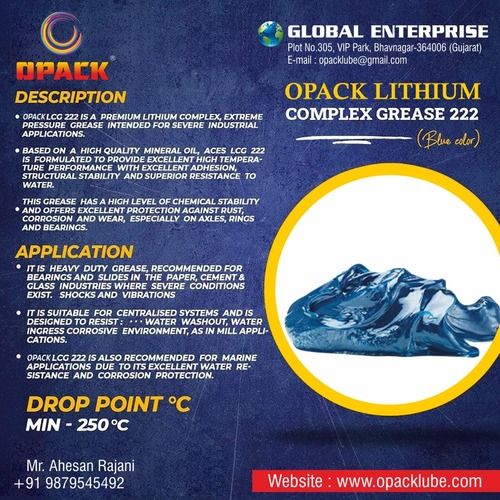

High-Performance Lubrication for Critical Machinery

Designed for demanding environments, Lithium Complex Grease delivers smooth, tacky consistency and reliable lubrication for automotive and industrial bearings, chassis, and wheel assemblies. With excellent shear stability and corrosion resistance, it performs flawlessly under heavy loads and elevated temperatures, reducing wear and tear and extending maintenance intervals. This grease is an ideal choice for equipment requiring consistent protection and long life.

Versatile Application and Packaging Options

Perfect for a wide range of machinery and equipment, this grease accommodates various operating conditions. Offered in multiple sizes ranging from 500 g cartridges to 180 kg drums, and packaging types like buckets, tins, and standard export packaging, it ensures flexibility to suit both large-scale industrial needs and smaller, targeted applications.

FAQ's of Lithium Complex Grease:

Q: How should Lithium Complex Grease be applied to bearings and chassis components?

A: For optimal performance, clean the component thoroughly before application. Use a suitable grease gun or dispenser to apply the grease evenly around bearings or chassis; avoid over-packing. Regularly monitor and reapply as required by maintenance schedules.Q: What are the primary benefits of using this lithium complex grease in high-temperature operations?

A: This grease features a high dropping point (>250C) and excellent oxidation stability, making it suitable for high-temperature environments. It maintains consistency, minimizes leakage, and ensures sustained protection under thermal stress.Q: Where can Lithium Complex Grease be utilized effectively?

A: It is ideal for automotive wheel bearings, chassis components, industrial bearings, and assemblies exposed to heavy loads and fluctuating temperatures, providing reliable lubrication and protection against corrosion and water ingress.Q: When is it necessary to re-grease equipment with this product?

A: Re-greasing intervals depend on operational load, temperature, and exposure to contaminants. Routine inspections can inform maintenance schedules, but generally, reapplication is recommended every few thousand operating hours or as specified by equipment guidelines.Q: What process ensures its corrosion resistance and oxidation stability?

A: The grease is formulated using a lithium complex thickener and blended with high-quality mineral oil and additives. This composition enhances resistance to moisture, prevents metal corrosion, and ensures long-term oxidation stability, verified by tests such as copper corrosion at 100C for 24 hours.Q: How does this grease perform under heavy load and high shear conditions?

A: Thanks to its high shear stability and consistent viscosity, the grease effectively minimizes mechanical breakdown and maintains a protective film, even in components experiencing repeated movement and heavy pressure.Q: What is the recommended shelf life and storage condition for Lithium Complex Grease?

A: The product offers a 24-month shelf life when stored in a cool, dry place, away from direct sunlight and sealed in its original packaging to maintain its quality and performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Lubricants Oil' category

|

GLOBAL ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |